Wehttamman asks: My dad and I once built a go-kart from chipboard, pram wheels and an engine from a lawn mower. It didn't work... so tell us about your favourite things you've made, and whether they were a triumph or complete failure.

(, Thu 11 Oct 2012, 12:00)

This question is now closed.

I built these two Daleks between 2005 and 2007. The black Dalek is all made of wood (various thicknesses of plywood and MDF) and non-operable, but the blue one is all-fibreglass and can be sat inside, steered around, etc. All the metal bits are in aluminium. I did buy in the hemispheres from a guy who custom-moulds them for Dalek builders. Someone else made the Tardis for me! If you're interested in Dalek building then www.projectdalek.com is the place to go.

(, Sat 13 Oct 2012, 12:10, 14 replies)

Having no space for a full sized cabinet, I built this:

Build blog here: minicade.blogspot.com

(, Thu 11 Oct 2012, 14:28, 9 replies)

Going from this...

to this

in the space of just over a year. I did everything; welding, painting and mechanical, including a full brake, suspension and engine swap. It successfully passed its MOT two weeks ago.

18 months ago, I'd never used a welder or held a paint gun.

(, Thu 11 Oct 2012, 13:03, 19 replies)

For some years I've been working on a large model of the Moon - well, the nearside, anyway. It's about 50cm across, a size chosen to be as large as possible while still able to fit through doorways. It's made of fibreglass, with the surface modelled in Milliput, working by eye from maps and photos.

The project has been on hold while my daughters were young (kids are Time Vampires, and this is a long process) but I'm planning to get back into it soon.

Here's a picture; one side is the real moon, the other is my model. Can you tell which is which?

Obsessed? Me? Well, the clue's in the username...

(, Thu 11 Oct 2012, 15:08, 10 replies)

As a child I was forever dismantling anything I could get my hands on and trying (usually unsuccessfully) to make build new, better things. As I've grown up, my access to tools and knowledge of physics has improved; this has however had the result of increasing the frequency of both successful creations and disasters.

Earlier in the year, I decided that an arc welder would be a useful thing to own and would increase that number of other unwise things I could build. Now any sensible person would at this point would have checked out ebay or screwfix; in case it was not already obvious, I'm not that sensible. I logged into freecycle and posted, offering to save people a trip to the tip by taking their old broken microwaves off their hands.

There are lots of fun bits & bobs inside an old microwave, but for this particular project I was after the transformers; I salvaged 2 transformers and with the aid of an angle grinder, an oven, a variety of odd bits of wood and a mallet removed the original secondary windings then replaced them with some nice thick copper that I bought online.

Now that I had two transformers, I bought some car battery cable, a huge crocodile clip and a welding rod holder and wired it all up. I plugged both the transformers into a multi-gang extension lead and I turned the mains on. There was a nice satisfying buzzing sound, but as soon as I touched the welding rod to the scrap of steel I was using for the test the fuse blew. This was obviously drawing more than the 13A that the sockets in the garage can supply. Now clearly at this point the correct course of action would be to consult an electrician in order to install a dedicated 30A circuit for the welder; I didn't have an electrician handy, but I did have two 13A sockets in front of me. A little test proved that while 13A wasn't enough, 26A was plenty.

Once I had a working welder I set about welding every piece of scrap steel I had to hand together; this kept me occupied for a few hours, but suddenly the welder stopped working properly - it would not strike an arc and was making a much louder buzzing noise. I casually lifted my mask to see what was going on, and instantly knew what the problem was: the 3" flames coming from the top of each transformer.

After much swearing and fumbling with the power switch with welding glove clad hands, I disconnected the electricity and put the fires out. While the primaries were ruined, luckily enough the secondaries I'd wound survived. I went back to freecycle and managed to find a couple of replacement transformers, with which I rebuilt the welder. This time I left the thermal safety cutouts in place.

It has proved useful for building a variety of other things, the most useful is probably my wood stove thingie:

and the least useful is probably the swiss army teapot:

the welder was too powerful and made lots of holes; it's useless as a teapot and most of the other tools are impossible to use without having a teapot in the way.

Shameless link to my blog with more details

(, Thu 11 Oct 2012, 18:21, 7 replies)

Sadly I no longer seem to have a picture of it, so a description will have to suffice.

When I was in engineering school, I was in a class where they paired up engineering students with sculpture students, gave us loose guidelines and sat back to see what we would create. My partner was a guy named Morgan, a typical art student in old stained tee shirts and jeans with hair that stuck up in all directions. Obviously we hit it off instantly.

I had made a silly gizmo out of a vibrating motor from a pager and a couple of paperclips. I named it the Spazzbot as it jittered all over the table when I switched it on, causing all who saw it to involuntarily giggle. I showed it to Morgan and his eyes lit up. "Let's make a six foot tall one!"

The idea made me grin, so it had to be done.

I went diving in the dump and found an old clothes washer and took out its motor. At home I tested it and found that it worked just fine. I estimated its speed to be about 10 revolutions per second. I guessed that I'd want about 10 lbs of lateral thrust, so based on that I did some quick calculations and determined that I would want about a pound of weight at six inches from the axis. I searched through the scrap iron pile and found a couple of chunks of bar and got someone to weld it on (I wasn't allowed, as I wasn't a sculpture student), then found a small chunk of iron for the end to be the weight. It didn't look like enough, so I got a much larger chunk and got that welded on.

Meanwhile we constructed a big thing that looked like a bastard hybrid of a lawn chair and a daddy longlegs. We put a plate at the top to bolt down the motor, so I did so and attached the weight. I then put on a power cord. It was ready for a test.

Only thing was, Morgan wasn't there. But being an impatient bastard I carried it outdoors and dragged out a cord with me to try it on my own anyway.

I stood with the plugs in my hands, and had a moment of caution. I hunkered down on the pavement, well below the level of the motor, took a deep breath and plugged it in.

With a shuddering roar the thing leaped from the pavement, gaining about a foot of air before landing. I yanked out the plug before it could get me, then stared at it like Frankenstein watching his monster rampage. Holy shit, I should have stuck with my calculations. Half of the welds on the frame had popped loose from less than a second of power.

Right about them Morgan showed up. "What happened to it?" I described my experience and his eyes lit up. "Do it again!"

Oh FUCK no.

I cut back on the weight and we displayed it for the class. The art students crowded close as it shuddered menacingly across the floor at them while the engineering students and teachers cowered against the wall.

We got an A.

(, Thu 11 Oct 2012, 22:11, Reply)

We got donated another, identical bike.

She was too big for them both, and her wee sister already had a bike that was big enough for her.

So, I made a Siamese Bike.

www.flickr.com/photos/yokelinc/7013695663/in/set-72157629298416288

There's a whole set of pics of the build process there: was a marvellous way to spend a weekend.

(, Fri 12 Oct 2012, 19:00, 4 replies)

I’m quite sure any rational bloke would insist when it comes to desirable gadgets an improvised flamethrower is right up there with a Jessica Alba Android and TeleportationTrousers, therefore not technically a pointless experiment. However, whilst pyrotechnical experimentation should always be nurtured in the young and reckless, the choice of firing range in this instance may be at best filed as ill advised.

Many moons ago I worked for a fairly rubbish ‘New Media’ company with a lot of bored, disillusioned staff. Jinks were always high. We had a set of steak knives in the kitchen, not sure why but they were perfectly balanced for my burgeoning knife-throwing act – until that is the semi-psychotic boss (same bloated buffoon as in my ‘Only 14 Hours to Bristol’ post) raged into the studio during an all staff meeting demanding to know who had been using his office door for 'bloody knife throwing practice'. Cue blank looks all round. I did find it indicative of our work ethic that he immediately (and rightly) assumed knife throwing had occurred. Other experiments included creeping up behind people on the phone and liberally wrapping parcel tape round their head – securing the phone to their noggin (this works best when they are also resting their chin on their free hand so you can cocoon that too) thus ensuring they must continue an (albeit muffled) conversation with Mr Self Important Client Tosser. Other japes involved cutting the corners off large boxes then arranging the boxes as crumple zones for stunt man ‘death’ leaps from filing cabinets. Using the wet & dry vac to hoover up peoples coffee from their mugs in one greedy slurrrrp always got a response too - usually ‘for fucks sake Spimf, fuck off will you, you fucking idiot’. Shooting out the bulbs on the desk lamps across the room with an air pistol tended to unsettle/enrage the occupant of the workstation a fair bit as well. So you get the picture – a committed and focused bunch of highly trained imbeciles.

One particularly slow day I spotted some large heavy-duty cardboard tubes lying there temptingly in a quiet corner. Like any right minded person my immediate thought was: Hmmm… Big Arnie-style RPG launcher i think! So I chose a fine sturdy tube about 4 foot long with a plastic end cap, then selected a slightly thinner tube that would fit nicely inside. A great big wodge of bog roll was taped around one end to make a snug and effective plunger for my makeshift munitions. Initially, this was simply ‘plunged’ to make the plastic end cap fly off with a satisfyingly low frequency ‘THHHONK’. Put simply i had fashioned the worlds biggest pop gun.

Soon my bodged bazooka sprouted a shoulder strap, side handle, plunger grip and nicely weighted cardboard ‘RPG’. Menacingly, I strutted around the studio attempting to shoot large things off high shelves and generally breaking stuff. With it's Kappa board fins and conical nose my ‘RPG’ flew surprisingly well. Boredom however, is a relentless staggering zombie that never lags far behind dear Spimfy. It was then I spotted the lighter fluid we used to clean Spraymount off stuff. I think I may have heard a small internal ‘ping’ as a little light bulb fluoresced in my head. A fist sized ball of bog roll was given a liberal soaking, lit to a near invisible Sambuca style blue flame by a willing assistant then rammed down the barrel with a broom handle, the plastic end cap was then popped on to provide a bit of back pressure. Clearly the restricted amount of air inside would only last so long, so launch had to be hasty. This however meant aim was a secondary consideration. I plunged the fucker with aplomb.

Fuck. Me.

It would be no exaggeration to say ‘a fucking great big fireball’ streaked from the end of my cardboard contraption with quite spectacular results. The pressure combined with a sudden rush of nice oxygen rich air produced angry red and yellow flames. It made a fantastic roaring noise as it soared across the studio trailing acrid black smoke and a deep thud as it slammed into the window recess resulting in an even bigger ball of flames. HOORAY! Everyone whooped and cheered - the few sensible ones (developers mainly) standing well back, shaking their heads and muttering about inadequate fire exits. The flames rapidly subsided to a little smouldering clump of blackened bog roll - the hilarity waned in harmony. Then, quite unexpectedly... Whoosh! The fabric window blinds went up in flames – big style, eagerly assisted by the dust and cobwebs around the ancient window frame (did I mention our office was a converted mill in a World Heritage site? Probably best not to). Dust and cobwebs and dead spiders burn like a motherfucker by the way, which I discovered while trying to ‘clean’ my garage with a blowtorch once.

In a blind panic I belted across the room and (with some difficulty) yanked the burning blinds down and proceeded to stamp on them with some considerable urgency. This had an immediate effect; being that it set fire to my shoes. I can honestly say the spectacle of me rain dancing with flaming feet did seem to lift the mood for a while.

A couple of days later the (increasingly psychotic) boss was eyeing the scorched, melted patch of fuzzy office flooring and looking for answers. Blank faces again. Good job he didn’t turn round to see the hastily installed non-matching window blinds stolen from another department.

length? fully extended about 5 foot mate.

(, Thu 11 Oct 2012, 16:12, 1 reply)

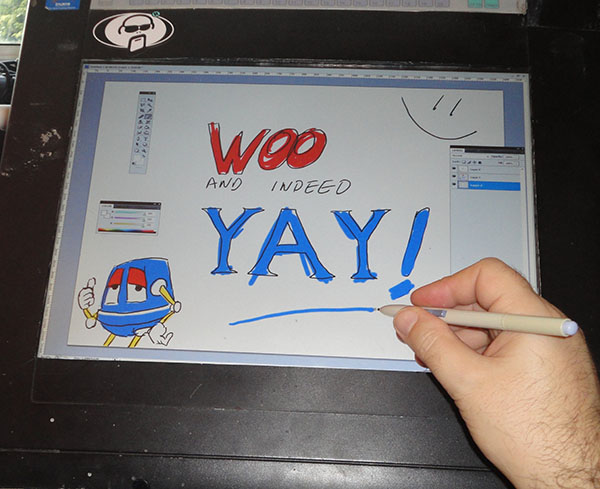

A few years ago I was on the Wacom site oggling cintiqs and swearing at teh ridiculous prices and thinking "surely that's just a monitor mounted over a tablet", and "I wonder what the read height on my tablet is?". I suddenly found myself buying for-spares monitors, getting a larger Wacom for free, and buying a dremel.

The old girl got an upgrade last year. The screen was suffering from age and long term UV damage, and the Wacom part was serial so not supported in windows 7. A mate had written a programme to use on a teensy (a programmable chip) that converts serial to USB. The teensy also gets rid of the Wacom power supply and passes on USB power. and I found a new screen that ups the resolution to 1600 x 1200.

Edit- there's a rather rambling build log here www.bongofish.co.uk/wacom/wacom_pt1.html

(, Fri 12 Oct 2012, 20:21, 8 replies)

I made the crap tank from Kitchen chopping board, bicycle chains, aluminium pipe and 9.6v Tesco Drills:

www.youtube.com/watch?v=b59fJSmncJg

It fires at 30 rounds per second and the BBs come out at a shade over 306mph. It's more fun that you'd believe!

;-)

(, Thu 11 Oct 2012, 13:39, 3 replies)

In 2007 I bought this ruin:

It's about half a 1970 BSA bantam. The only bits not in the picture are a knackerd chain and the logbook, the bodywork and engine having been stolen. Not a particularly inspiring bike, and not the best start for a first restoration-but I wanted a classic, and this was it.

There then followed 2 years of spannering, painting, fettling, buying bits, refettling, unspannering, buying more bits...pictures here: @N03/sets/72157614315853615/

"www.flickr.com/photos/35741071@N03/sets/72157614315853615/

I decided to do it as a mini cafe racer, being as the engine is still quite popular for tuning and racing. This caused many headaches. Most of the modifications were done at least 3 times. The mudgaurd had to be redone when I realised the original held the forks stiff-after I tried replacing the bushes. The rearset footpegs were a huge headache too, it wasn't until I came to fit the chain I realised they were in the way. The seat took 3 months, made from some scrap steel, a camping roll mat, a tarts leather skirt and a load of fibreglass-man, the fumes! I carefully smoothed the ports in the engine, had the crank rebuilt and the engine bored to a whole 185cc (that and the tyres are the only bits I didn't do myself), rewired it...I shudder to think what it cost, if I try totting it up I give up after a grand.

I rebuilt the engine in January, and after fitting it into the frame it fired up pretty eagerly: www.flickr.com/photos/35741071@N03/4281076209/

By March I'd built this:

The second ride (once I'd found the knackered ignition coil) was incredible. The engine was incredibly wheezy and slow at first, but as it warmed up it woke up. Almost as though it was remembering what roads are for after 14 years sat in a shed. It is a great feeling to ride something you've built, nut and bolt upwards.

Since I posted this in Beautiful moments part 2, the bike has continued to evolve. Nice new halogen headlamp, and a couple of exhausts to make it less gobby, smoother and quicker. I've moved to Derby now, so straight throughs are a bit anti social. Sadly this year it's got a bit sidelined as I've been building a workshop, like a twit I insured it then havn't MOT'd it since June, so it's not ran for a bit. Just before laying it up I fitted a new mikuni carburettor, which made it much smoother. The tale will continue...

(, Thu 11 Oct 2012, 13:22, 6 replies)

Not me but one of my students who decided to make a rugby training aid for a technology project.

All went well with the small scale tests which sent ping pong balls scurrying around the classroom. Then he ramped it up to full size and used a car starter motor to launch a full size rugby ball...

..Straight through the classroom wall!

(, Tue 16 Oct 2012, 12:08, 4 replies)

As a structural engineer I have alot of good answers, like a film studio. But my crowning achievement is when I built a 7ft entirely edible cake.

It was a competition for the queens jubilee to build the tallest and most interesting cakes between 4 groups of engineers. 3 of which had full corporate backing, Arup (wobbly bridge fame) had bought cement mixers and had all the junior engineers on shifts for a week. Unfortuntely our team weren't as well resourced, we represented the Institution of Structural Engineers and were formed of myself, my mate and 2 random students who we met for the first time 2 days before the event. Our humble background didn't stop us though, armed with 100kg of chocolate and 30kg of Rice Crispies we moulded our cake to look like a giant cake stand with pillars and platforms. We fixed it together with melted chocolate and covered it with smaller cakes, winning the Most Beautiful Cake award!

Of our competition 2 of them collapsed, first Arups, due to over ambition then expedition engineering due to the rain!

So yes, 7ft, totally edible, no dowels, metal, wood or plastic. Chocolate and rice crispies are a very tasty building material.

the best picture on the net is on MSN.

news.uk.msn.com/diamond-jubilee/your-diamond-jubilee-pictures

To see arups collapse check out youtube.

youtu.be/xiLjBM3SEfI

p.s. the crowed took it all away, bunch of scavengers. Even the pieces from the ground!

(, Sun 14 Oct 2012, 23:43, 2 replies)

After suffering with a cat who insists on climbing on every kitchen surface and realising that a squirt of water was the best defense against paw prints everywhere, I decided to build an electronic squirter.

The device consists of an infra-red beam and sensor which, when interrupted by a cat*, activates a pump that takes water from a box and fires it in the direction of the cat*. For added scariness I've also wired in a device that creates a hissing sound when triggered**.

*or forgetful human

**I don't personally find it particularly scary.

(, Fri 12 Oct 2012, 12:22, 3 replies)

As a kid (I'm 34 now) I had a CPC464, which other Brits will recognise as Alan Sugar's answer to the Commodore 64. Like a lot of 80s kids I learned the BASIC programming language and did a bit of coding... all well and good.

Then I inherited a 2nd CPC464 from a family friend whose kids had grown out of it.. Clearly 2 computers must be networked for maximum efficiency. The CPC464 had no networking hardware apart from a modem that I couldnt afford to buy, I knew nothing about network protocols, but I did know about radio, and electronics

After much cursing, soldering and coding it was done: Home made network adapters connecting the Sound Out port on each CPC464 to the Joystick port of the other via a home-designed and built frequency to voltage converter driving a switching transistor, built out of components bought from Tandy (Radio Shack)

They could act as teletype terminals. The networking protocol wasnt based on data per se. The messages were passed from one PC to the other via Morse Code, and all the coding was to design a program that would time the pulses, when it met a long delay it knew it was at the end of a letter, could compare the saved pulses to a database of letters and write the nearest match to a buffer

With care it was possible to type on-screen using just a remote morse key although better reliability was had with 2 computers as the timing was more predictable

Stage 2 involved going wireless. This was quickly forbidden as the best frequency I could find / achieve for data morse code caused harmonics that overrode Radio Four (turned out multiples of the frequency are a problem)- and morse data networking over home made transmitters wasnt a great success

However

10 years later a major UK PC magazine had a write in contest for 'whacky tech achievements'. I sent my circuit diagrams and a printout of my code.

The 19-inch Taxan monitor I won as a result was huge, and very welcome. At the time (Celeron 500mhz era, for context) that was unusually large. It still works.

(, Thu 11 Oct 2012, 18:07, Reply)

at the age of 12, my brother suddenly became very secretive, often locking himself in his bedroom for hours at a time. were i older, i'd probably have assumed he'd discovered wanking. curiously, his desire for cans of coke increased greatly. then, my best red nail varnish disappeared. it was all very strange.

after 6 months, all was revealed when my brother unveiled the model of a laborghini diabolo that he'd built from metal pieces snipped from coke cans and painted pillarbox red with my nail polish. it was beautiful, a true work of art, lovingly crafted by a young boy who should be rightly proud of his work.

the twat binned it 2 days later because he was bored with it.

(, Sun 14 Oct 2012, 19:08, Reply)

I made this a few years ago for the kids. Still really proud of it and the fact that it is still played with.

It's amazing what you can do with a sheet of MDF and several hundred roof tiles.

(, Wed 17 Oct 2012, 19:22, 5 replies)

Having worked at a company that made atomic clock and GPS-based frequency standard equipment, I had access to scrap 19" rack hardware. As my brother wanted a slave amp for his bass rig to power his outboard speaker cabs, I knocked up one in a 2U rack using a 2N3055/MJ2955 transistor stage and a preamp kit board from the infamous Maplin, power supply designed by myself and cabled to the same standard of work that we used for our military clients. As a bonus, I asked the tool room manager if he could engrave the front panel with a unique design so that it was obvious this was a custom piece of hardware. The result was the DOM-200 (for my brother is Dom and it was a 200W RMS amp).

A few years later after I had moved jobs to testing mixing desks, a friend of mine's husband asked how difficult it would be to make a combo mixer amp for his gigging career as the keyboardist in a Blondie tribute band. There was nothing on the market that would do what he wanted, to be able to hook up three mono keyboards, a stereo keyboard, into a power amp which was compact enough to fit into the corner of the gig van but also have 300 Watts capability.

The parameters for enclosing the available 12" or 15" bass/mids would have made the cab woodwork rather large so I had to go with the only 10" 300W speaker I could find which also neccessitated a rather peculiar crossover frequency to the horn, the only one of which I could find was used in a JBL unit- fortunately JBL speakers were owned by the same group (at the time) that owned Allenn & Heath, so a quick word between shop floor supervisors and a scrap unit was given to me for my task.

As nearly all gigged amps get bashed about, choosing the typical chipboard seemed to be a bit short sighted so I got a 1/2" thick 10x6 foot thick sheet of marine ply and had to saw it up into the right pieces to form the cab. 120 2" screws held it together. Ripper.

Having access to certain schematics, I 'borrowed' a four channel EQ design from one of the A+H mixer input stages and designed/etched/drilled the channel and mixer PCBs for the inputs (3 mono, 1 stereo)to fit into a 3U front panel. This time because of the complexity of the milling and engraving of the front panel, I didn't think that it was in 'favour' territory to ask my friend the tool room manager to do it for free so he quoted me £85 for the work which was fine. The input, EQ and mixer stage was done, the speaker and crossover section was done, the cabinet was finished with buffalo vynide cloth, the speaker and horn was mounted- now the power amp. Design my own? Follow a reference design?

Fuck that shit, I'm not stupid. Bought a pre-made MOSFET 450W amp module from OMP and shoehorned it in. Presto, the job is done. Apologies for the crappy quality of the picture but this was from the days before digital cameras, and my pocket compact and rubbish scanner weren't up to much in those days...

(, Wed 17 Oct 2012, 14:33, 4 replies)

The first job was to choose each tube and a friend and I chose a mix of Columbus Max and Max OR tubes, I wanted to use 26" wheels for strength and a 50mm travel fork on the front for those really bad roads. Finally it was put together into a frame jig and braised together by my friend who was a craftsman with a gas torch. Once it was done, I painted with a couple of rattle cans and built it up with a mix of Suntour XC Pro, Shimano XT and a set of old Deore thumbshifters. However the flat bar made it too slow, so I replaced that with a set of touring drops and some Tiagra STIs and that bike became a super fast beast of burden. In the end and after a particularly nasty crash that dented the top tube, I retired the bike and that frame now hangs on my bedroom wall, covered in soft toys.

(, Fri 12 Oct 2012, 2:12, 7 replies)

I was really proud of it, it'd taken months at woodwork. Then Barry Kent smashed it up and went off laughing. Just my luck!

(, Thu 11 Oct 2012, 22:58, 2 replies)

No, seriously.

I needed a place for my tools and to work in. The back yard had a forsythia bush that I hated anyway, so in that corner it went. I cut down the forsythia, leveled out the ground to the best of my abilities, then got some of those blocks with a cross shape cut in the top for building decks and used those for my foundation. I then used pressure treated 2x6 for the floor joists, put down OSB for the floor, and framed in the walls.

And then it rained for two days.

The following Friday was clear, so I planned on spending the weekend putting on the walls and roof.

And then it rained for two days.

Right, now things are starting to warp. Five days of sunshine so at least now it's dry. Friday rolls around, so I planned to finish it that weekend.

And then it rained for two days.

On Tuesday I finally asked my boss if I could take the next day off and explained why. He tried to stifle a chuckle unsuccessfully, but let me have the time. I got out there and put up the roof (corrugated galvanized steel) and the lower parts of the walls, and started on the upper parts before it got dark. I planned on finishing off that weekend, especially as Friday was again clear.

And then it rained for two days. But I didn't give a fuck as I now had a roof over me and could cut the remaining wood and put it up in the rain.

The end result was a 12x12 building with a second floor, a picture window, a regular window and a 4x8 door with work benches built along the walls. I ran power to it with an extension cord (because of zoning laws) and that has been my workshop for the past four years. I have made many things in it.

And when it rains on me and I hear it drumming on the metal roof, I smile and extend my middle finger at the sky.

(, Thu 11 Oct 2012, 21:09, Reply)

For some reason new build houses seem to come with beige carpet. Not just any beige carpet, but cheap thin beige carpet which the day after moving in already looks awful.

So you can imagine after 2 years of pushchairs, feet and furniture in rainy devon it looked like a dogs dinner.

So I decided to really go for it in a replacement flooring. The house was an awkward wedge shape so nothing was going to be easy but I ordered a pallat of really lovely Brazilian Slate tiles.

Out came the old carpet, the underlay, carpet grippers, the skirting boards. Then through to the kitchen, I shifted furnishings, the fridge, washing machine and even the fitted kitchen unit end panels and plinths.

I set about it and over the course of 4 weeks laid the most beautifully planned floor you can imagine. It was under the skirting, cut to angles so it flowed in straight lines parallel to walls meeting adjoining rooms with a foot plate dividing the rooms in a continuous sea of slate through the ground floor. Even in the downstairs loo the skirting was replaced with a section of tiles to make mopping the floor an easy job. Once back together I was really really proud of it, the neighbours admired and complimented me on the workmanship.

I think I was pretty much laying the last few tiles when the ex-wife decided she'd rather shack up with someone else. And by that I mean that I had to move out so he could move in.

Wind on 2 years and the divorce is done and the house is sold. Went back for one last look at the now empty house only to see the tiles scratched and neglected where metal frame chairs were dragged along the floor. What a bummer.

Floor still looked good though.

Tiles, even after years of abuse they'll age better than your ex.

(, Thu 11 Oct 2012, 13:04, Reply)

A school craze for pea-shooters (well, spit-ball shooters really) was in full swing. But point, shoot, repeat seemed a little pedestrian to me; clearly I needed More Power.

So I built a machine-pea-shooter: a ten-shot repeater, something like a minigun, with ten barrels and a sliding mouthpiece. I could shoot one at a time, or unleash a deadly hail of spit-balls at my cowering victims.

Unfortunately, my playground triumph was short lived, as a) it took about five minutes to re-load, and b) I got beaten up for being a smart-arse.

(, Tue 16 Oct 2012, 11:06, Reply)

I recently got my hands on an old rotavator, before use I had to make several 'repairs' as it had been sat in a shed for a decade. The starter clutch was prone to jamming, stopping the flywheel and in the process breaking the shear-pin; my solution was to retrofit an electric start feature (read, a big socket, an extension bar and a power drill). The other controls weren't in mint condition either, operation was via yanking and twiddling control cables at the correct time.

Once I'd turned the lawn into a small scale replica of the Somme, my attention turned to the little petrol engine that was now just sat in the garage. After some careful thought I managed to work out that what was missing from my life: a hugely inefficient, cumbersome and risky way to make my lunch. I detached the blades from the bottom, ratchet strapped the engine and controls onto a workmate and made a start on the engine-masher interface. In the end I settled for jubilee clipping the masher to the end of a bit of broom-handle, poking that through one of the work-mate holes and tying a spring on with a piece of string to return it to the 'up' position. The down stroke was powered by screwing a block of wood to the flywheel of the rotavator.

Once I'd lined things up and shaped the wooden block such that it would smoothly push the masher rod down, I got the drill out and started her up. It worked! The masher flailed up and down like a tigger on speed, and nothing seemed to be going wrong. This inspired me go from idle to full throttle, at this point the whole contraption started to topple; I managed to grab it as it went over, cutting the engine by touching together two particular exposed wires. Unfortunately the exposed flywheel had made short work of demolishing the whole masher mechanism; those glorious few seconds of optimism were cruelly crushed as I came to the realisation that I would be forever stuck in a dreary life of mashing potatoes without the excitement of potentially maiming myself.

(, Mon 15 Oct 2012, 22:13, 2 replies)

...I made a lifesize caricature puppet head of Nick Griffin and did some mini-pyro tests for a film, both of which are described in this old b3ta thread, so I won't go in to any more detail here:

www.b3ta.com/questions/amazingprojects/post1439494

More recently, I made a small caricature head of Seb Coe intended for some stopmotion animation tests, but I wasn't happy with the way it turned out, so I'm doing more work on other subjects:

And in the last week I've built a phonograph cylinder shaving machine (you use it to smooth off blank wax phonograph cylinders for recording on) and a cutting stylus made from glass for an Edison phonograph recording head:

The reason there are all those labels on the photos, which will mean fuck-all to people here, is that I put those images together earlier as information for someone else who wants to have a crack at recording on wax.

And with those I've been experimenting with recording on wax cylinders using an Edison phonograph:

youtu.be/2Nz-V208ux4

(, Mon 15 Oct 2012, 1:31, 3 replies)

I made a radio controlled bedroom door opener at the age of 12, as I was too lazy to open and close my bedroom door.

I also was interested in radio about that time and realised using my Chinese walky talkies and a copper wire attached to the telephone poll at the end of the garden, which was wrapped around the aerial of the walky talky, would extend the range..I lived on top of a big hill.. my friends and I could run a pirate radio station from my bedroom and destroy what everyone was listening to around the classic fm range..within a certain distance of my house..hahaha until a neighbour complained...

I worked as a technician for the NEC in B'ham for a while and everything we had to make there was held together with gaffer tape or ratchet straps.. most things generally only survived a few hours. Best thing i made there in down time over the summer when we were meant to be doing repairs was A cross bow, also a hover craft.

(, Sat 13 Oct 2012, 0:59, 6 replies)

At a very drunken birthday party, the birthday girl said that the thing she'd like most in the whole world would be a dildo with the head of Stuart Pearce as the knob.

Now I know that sounds like a set-up for a pun, but it really isn't. Nor is it a tortuous way to get to a "Stuart Pearce is a bell-end" line. It's really genuine: she fancied him, and thought it would be the ideal sex toy, to fill those long half-time delays.

Being drunk, I told her I'd make one (after asking who the fuck Stuart Pearce was - I know nothing about football). Bizarrely, when I sobered up it still seemed like a fun challenge, so I did. I carved a large cock in clay, then modelled his face on the glans - I used the famous pic of him crushing Gazza's bollocks as a reference. It turned out really well, easily recognisable even though it was the first time I'd tried to model a real, living person's face.

Then I cast a fibreglass mould, and from that produced a silicone wang. She was, as you'd imagine, extremely startled when I presented it to her, the next weekend - it was, after all, her heart's desire. Well, perhaps a little lower than the heart.

Unfortunately no pictures exist, but I do still have the mould somewhere. Strangely no-one has ever asked me to make another...

(, Fri 12 Oct 2012, 16:21, 5 replies)

I made this in 2007 for my daughter's birthday. Got the plans from a Garden Projects DIY book, modified them a little, and built it effectively from scratch over the course of a couple of weekends. Five years on and it's still standing.

It's not a shed, by the way!

(, Thu 11 Oct 2012, 14:08, 20 replies)

Obviously this made the mods insanely jealous so they banned him.

I should have called him 6yearoldboybot and then they would just have tried to have sex with him.

(, Thu 11 Oct 2012, 12:31, Reply)

This question is now closed.